Top Signs Your Ropes Are Worn Out and Need Immediate Replacement: How to Inspect and Stay Safe

October 2, 2025

Ropes that show wear risk sudden failure, posing serious safety hazards and costly downtime. Understanding the signs that indicate you need to replace your current ropes helps prevent accidents and extend equipment life. This guide defines visual and tactile damage signals, outlines inspection methods, covers lifespan criteria, and highlights unique indicators for climbing, wire, and marine ropes. By the end, readers will know when to retire worn lines and where to source custom replacement ropes for reliable performance.

What Are the Most Common Visual Signs of Rope Wear?

Visual wear signs reveal a rope’s structural degradation by exposing abrasion, fiber breakdown, or color shifts, which enhances early detection and prevents catastrophic failure. Inspecting the sheath and core visually offers immediate cues on rope health.

Identifying Fraying, Abrasion, and Discoloration on Ropes

Before listing, run your eyes along the rope length to spot surface damage.

| Sign of Wear | Description | Implication |

|---|---|---|

| Fraying | Individual fibers poke through the sheath. | Indicates external abrasion and reduced integrity. |

| Abrasion | Smooth, flattened areas where friction has worn the strands. | Weakens the rope’s outer layer. |

| Discoloration | Noticeable color shifts or fading. | Shows UV or chemical exposure weakening fibers. |

These signs collectively point to reduced tensile strength and signal the need for closer inspection of internal integrity.

Core Exposure or a Core Shot Indicates Severe Rope Damage

Core exposure, or a core shot, appears when the outer sheath splits and inner strands or core fibers protrude. This damage compromises load distribution and necessitates immediate rope replacement to avoid sudden breakage.

Flat Spots, Kinks, and Deformations Signal Internal Rope Damage

Flat spots feel thinner when squeezed and show uneven strand compression, indicating internal crushing. Kinks lock the rope’s lay and can introduce stress points, while deformations such as bulges signal internal fiber displacement. Each of these shapes predicts weakened performance under load.

How Do You Inspect Ropes for Damage: Visual and Tactile Techniques?

Rope inspection combines seeing and feeling to gauge overall condition and detect hidden flaws before they cause failure. A systematic check before each use maximizes safety.

Tactile Inspection Methods Effectively Detect Internal Rope Damage

Use these hands-on checks to reveal core issues:

| Method | Technique | Purpose |

|---|---|---|

| Pinch and Roll | Between thumb and forefinger along the rope length. | To sense flat spots, stiffness, or inconsistencies. |

| Bend over Edge | Bend the rope over a firm, rounded edge. | To locate spongy or crunchy areas caused by core delamination. |

| Measure Diameter | Use calipers at various points along the rope. | To identify internal wear or significant diameter variations. |

These methods uncover internal damage that eye inspections alone might miss.

Rope Inspection Frequency Varies by Type and Usage

Inspection frequency depends on rope usage and type:

| Rope Type | Inspection Frequency | Key Focus |

|---|---|---|

| Climbing Ropes | Visually before every climb; full tactile check monthly or after major falls. | Sheath integrity, core shots, flat spots. |

| Wire Ropes | Daily in continuous service; log findings for each lay. | Broken wires, corrosion, birdcaging, diameter reduction. |

| Marine Ropes | Weekly for UV and saltwater degradation, especially after heavy exposure. | UV fading, salt crystals, chafe, mildew, stiffness. |

Regular checks align replacement timing with real-world wear patterns to maintain safety.

When Should You Replace Your Rope? Key Lifespan and Usage Guidelines

Rope retirement criteria balance age-based limits, usage intensity, and manufacturer standards to ensure safe operation and cost-effective maintenance.

Age-Based Retirement Criteria Apply to Climbing and Wire Ropes

Climbing Rope Lifespan and Performance

Research indicates that climbing ropes, even when unused, degrade over time due to polymer fatigue. This degradation can compromise the rope’s ability to absorb energy during a fall, highlighting the importance of age-based retirement criteria. Petzl, Rope Inspection Guide, 2020

Wire ropes in static service often follow a five-year maximum in storage before requiring requalification to guard against material embrittlement.

Usage Frequency and Severity Impact Rope Replacement Timing

Frequent heavy-load cycles, severe falls, or abrasive environments accelerate wear. A rope used weekly under high tension often needs replacement within one year, while occasional recreational use may extend to three years under careful inspection regimes.

Manufacturers Provide Recommendations for Rope Lifespan and Replacement

The following table outlines manufacturer guidelines for retiring common rope types:

| Rope Type | Typical Lifespan | Replacement Trigger |

|---|---|---|

| Climbing Nylon | 5–10 years | Core shot, >5 soft spots, major falls |

| Galvanized Wire | 3–7 years | ≥6 broken wires in one lay, >7% diameter loss |

| Marine Polyester | 4–8 years | UV fading, >10% abrasion depth |

These guidelines align replacement timing with safety standards and preserve rope reliability.

What Are the Unique Wear Indicators for Different Rope Types?

Different constructions and environments produce distinct damage signatures that dictate specialized inspection focus and retirement actions.

| Rope Type | Unique Indicators of Wear | Safety Implication |

|---|---|---|

| Climbing Ropes | Fuzzy sheath fibers, flat spots from falls, sheath slippage over core, core shots. | Reduced energy absorption, increased risk of sudden failure. |

| Wire Ropes | Broken wires, inner corrosion, birdcaging (strand separation), >7% diameter reduction. | Compromised load capacity, high risk of catastrophic failure. |

| Marine Ropes | UV bleaching, salt crystals etching fibers, chafe, mildew, stiffness. | Loss of flexibility, reduced strength, unreliable handling. |

Climbing Ropes Exhibit Specific Wear and Replacement Signs

Climbing ropes show fuzzy sheath fibers, flat spots from falls, sheath slippage over the core, and core shots after severe falls. Each indicator reduces energy absorption and merits immediate retirement.

ASME Standards Define Critical Damage Signs in Wire Ropes

Broken wires, inner corrosion, birdcaging (strand separation), and diameter reduction exceeding 7 percent signal a compromised wire rope under ASME B30.30.

Rope Inspection and Safety Standards

Industry standards emphasize the importance of regular rope inspection to prevent accidents. These standards provide guidelines for identifying wear and tear, and for determining when a rope should be retired from service. American Society of Mechanical Engineers (ASME), ASME B30.30-2019

These defects directly decrease load capacity and require rope removal.

UV, Saltwater, and Chafe Significantly Affect Marine Ropes

Marine lines degrade via UV bleaching, salt crystals etching fibers, and chafe where ropes rub against hardware. Mildew and stiffness also indicate loss of flexibility, so replacement restores handling and strength.

What Are the Safety Risks of Using Worn Ropes and How to Prevent Injuries?

A worn rope presents a high risk of sudden failure, leading to falls, dropped loads, or equipment damage. Proactive inspection and timely replacement form the first line of defense against accidents.

Rope Failure Poses Significant Dangers and Potential Injuries

Rope breakage can cause uncontrolled loads to drop, resulting in severe crush injuries, falls from height, or structural damage. Even minor snaps can whip back and injure hands or face.

Regular Inspection and Timely Replacement Prevent Accidents

Consistent visual and tactile inspections catch wear before catastrophic failure, while adhering to lifespan guidelines removes compromised ropes from service. Combining these practices with professional replacement solutions minimizes downtime and protects personnel.

Rope wear progresses silently until a load-critical threshold is crossed. By spotting wear patterns early, following age and usage criteria, and swapping out frayed or deformed lines, teams maintain safe operations. For customized, purpose-built lines that match your exact specifications, explore “custom replacement ropes” to ensure optimal performance and peace of mind.

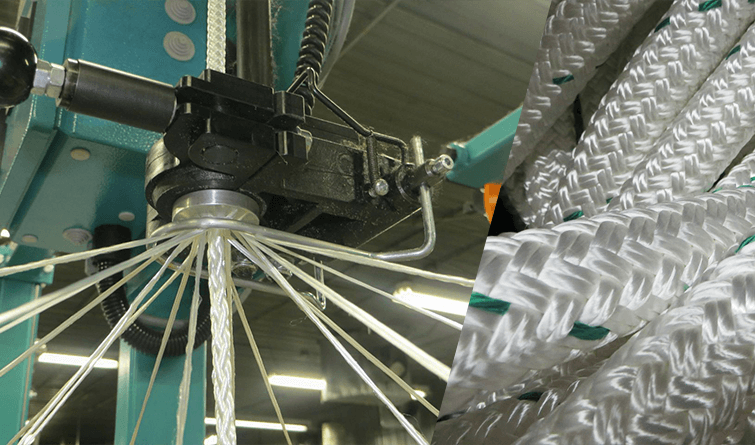

Ready for Reliable Performance with Braidlace?

Don’t compromise on safety. Ensure your operations are protected with high-quality, custom-fit replacement ropes. Get a quote today and experience the difference.