© 2019-2022 Braids and Laces Limited All rights reserved.

Powered by Digital Ink Technologies

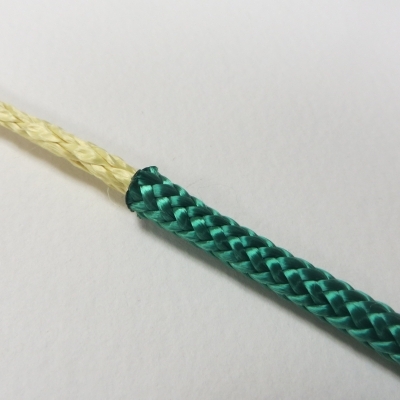

Kevlar has high strength, low stretch characteristics and high heat tolerance. A cover braided over the aramid fibre protects it from abrasion and creates a superior strength rope or cord. Custom made to order. $150.00 Minimum Order

© 2019-2022 Braids and Laces Limited All rights reserved.

Powered by Digital Ink Technologies

kevlar, parachute cord, aramid, rope, fiber, knot, nylon, model rocket, parachute, textile, braid, technora, wire, gear, sale price, add to cart, belt, fishing line, dupont, steel, polyester, abrasion, sling, price, yarn, vectran, webbing, kite line, flame retardant, cart, currency, anchor, fatigue, survival kit, polyurethane, length, benin, ripstop, united arab emirates, british virgin islands, tent, cable tie, cables, caribbean netherlands, caribbean, guinea, wire rope, creep, inch, deformation, weight, diameter, shopping cart, dimensional stability, construction, acid, customer, solvent, melting point, warranty, poi, rigging, manufacturing, weaving, carbon, packaging, twill, adhesive, composite material, customs, fiberglass, braided fishing line, electrical wiring, resin, cotton, roll

How to cut kevlar cord?

Cutting Kevlar cord requires specialized tools for best results. Use a sharp, heavy-duty wire cutter or scissors designed for tough materials to ensure clean, precise cuts without fraying. Consider sealing the ends with heat or adhesive to prevent unraveling.

Is kevlar rope good for a volleyball net?

The suitability of Kevlar rope for a volleyball net is notable. Its high strength, low stretch, and durability make it an excellent choice for withstanding dynamic forces during play, ensuring a long-lasting and reliable performance.

How much weight can a kevlar rope hold?

The weight capacity of a Kevlar rope varies based on its specific construction and diameter, but it is known for its impressive strength, often lifting loads from several hundred to over a thousand pounds. Always consult product specifications for exact ratings.

What is kevlar rope used for?

Kevlar rope is used for various applications requiring high strength and durability, such as marine, industrial, and rescue operations, as well as in sports equipment and outdoor gear, where low stretch and heat resistance are essential.

Does kevlar cord stretch?

Kevlar cord has minimal stretch compared to conventional materials. Its low stretch characteristics enhance stability and reliability in high-demand applications, making it an excellent choice for tasks requiring precision and strength.

How to cut braided kevlar cable?

Cutting braided Kevlar cable requires using a sharp utility knife or heavy-duty scissors. Ensure a clean, straight cut by applying firm pressure and cutting slowly to prevent fraying. Always wear protective gloves for safety.

What tools are best for cutting Kevlar cord?

The best tools for cutting Kevlar cord are high-quality scissors designed for tough materials, heavy-duty utility knives, or specialized wire cutters. These tools ensure clean cuts without fraying the cord, maintaining its strength and integrity.

Can Kevlar rope be used in water activities?

Kevlar rope can be effectively used in water activities. Its high strength, resistance to abrasion, and low water absorption make it suitable for marine applications, ensuring durability and reliability in challenging environments.

What are the advantages of Kevlar over nylon?

The advantages of Kevlar over nylon include its superior strength-to-weight ratio, exceptional heat resistance, and minimal stretch, making it ideal for high-performance applications where durability and reliability are critical.

Is Kevlar rope suitable for climbing?

Kevlar rope is not suitable for climbing. While it boasts high strength and low stretch, it lacks the necessary dynamic properties and shock absorption essential for safety during climbing activities.

How durable is Kevlar compared to other materials?

The durability of Kevlar compared to other materials is exceptional. Kevlar offers superior strength, resistance to abrasion, and low weight, making it significantly more durable than traditional materials like nylon or polyester, particularly in high-stress applications.

What properties make Kevlar ideal for ropes?

The properties that make Kevlar ideal for ropes include high strength-to-weight ratio, low stretch, excellent heat resistance, and exceptional durability, making it suitable for demanding applications where reliability and performance are essential.

How resistant is Kevlar to abrasion?

Kevlar exhibits exceptional resistance to abrasion, making it ideal for high-wear applications. Its advanced material properties ensure durability, allowing it to withstand significant friction and extend the lifespan of ropes and laces in demanding environments.

Can Kevlar cord be dyed for custom applications?

Kevlar cord can be dyed for custom applications; however, the dyeing process may require specialized techniques due to its unique material properties. It's recommended to consult with our team for optimal results in achieving the desired color finish.

What thickness options are available for Kevlar cord?

The thickness options available for Kevlar cord vary to meet specific application needs. We offer a range of diameters, typically from 1/16 inch to 1/4 inch, ensuring you can find the right fit for your requirements.

How to store Kevlar rope for longevity?

Proper storage of Kevlar rope is essential for longevity. To ensure its durability, store the rope in a cool, dry place away from direct sunlight and chemicals, preferably in a breathable bag to prevent moisture buildup.

Are there different types of Kevlar rope?

Different types of Kevlar rope are available, each designed for specific applications, such as textiles, marine use, or industrial purposes. These variations prioritize factors like strength, flexibility, and resistance to environmental conditions.

What safety measures should be taken with Kevlar?

The safety measures that should be taken with Kevlar include using appropriate protective gear, ensuring proper handling to avoid cuts or abrasions, and following manufacturer guidelines for use in various applications to maximize safety and effectiveness.

Can Kevlar cord withstand high temperatures?

Kevlar cord can indeed withstand high temperatures. It is well-known for its heat-resistant properties, allowing it to perform effectively in environments where other materials may fail. This makes it an ideal choice for demanding applications.

How is Kevlar rope manufactured?

The manufacturing process of Kevlar rope involves spinning high-strength Kevlar fibers into strands, which are then braided or twisted together to form the final rope. This results in a durable and heat-resistant product ideal for various applications.

What makes Kevlar cord ideal for sports gear?

The suitability of Kevlar cord for sports gear lies in its incredible strength, low stretch, and resistance to abrasion and heat, making it a reliable choice for high-performance applications where durability and performance are critical.

How to join two pieces of Kevlar rope?

Joining two pieces of Kevlar rope can be accomplished by using a sturdy knot, such as a double fisherman's knot, which provides a secure and reliable connection. Ensure that the knot is tightly secured to maintain the strength of the ropes.

Is Kevlar rope heavy or lightweight?

Kevlar rope is lightweight yet exceptionally strong, making it an ideal choice for applications requiring high durability without the added weight of traditional materials.

What is the lifespan of Kevlar cord?

The lifespan of Kevlar cord varies depending on usage and environmental factors but typically ranges from 5 to 10 years. Proper storage and maintenance can significantly extend its durability and performance.

Can Kevlar rope be reused after cutting?

The reusability of Kevlar rope after cutting depends on the condition of the cut ends. If cut cleanly and not frayed, the remaining pieces can often be reused for lighter applications. However, inspect for integrity before reuse.

What are the common applications of Kevlar cord?

The common applications of Kevlar cord include aerospace, automotive, military, and sporting goods. Its high strength and durability make it ideal for safety gear, towing, fishing lines, and outdoor equipment, enhancing performance in demanding environments.

How does temperature affect Kevlars performance?

Temperature affects Kevlar's performance by influencing its strength and flexibility. Kevlar maintains high tensile strength at elevated temperatures, but extreme heat can lead to degradation, while cold temperatures may reduce its flexibility.

What is the tensile strength of Kevlar rope?

The tensile strength of Kevlar rope is exceptionally high, typically reaching around 500 to 600 pounds per square inch, making it one of the strongest materials available for applications requiring durability and reliability.

How to properly maintain Kevlar cord?

Proper maintenance of Kevlar cord involves regular cleaning, avoiding exposure to harsh chemicals, and promptly inspecting for signs of wear or damage. Store in a cool, dry place to prolong its durability and performance.

What are the benefits of using braided Kevlar?

The benefits of using braided Kevlar include exceptional strength, durability, and low stretch, making it ideal for high-stress applications. Additionally, its heat resistance ensures reliable performance in extreme conditions, enhancing safety and longevity.