Nylon vs Polyester Marine Ropes: Which to Choose?

September 30, 2025

Ever felt your dock lines stretch too much and send your boat bouncing? Picking between nylon vs polyester marine ropes solves that confusion by comparing elasticity, UV resistance, abrasion tolerance and wet strength. This guide promises clear guidance on material properties, application tips, cost considerations and even alternative rope choices. You’ll learn core differences, best uses for docking versus anchoring, maintenance pointers, and when polypropylene steps in—all while spotting custom rope options from industry experts. Next we dive into the key material contrasts that shape performance at sea.

What Are the Key Differences Between Nylon and Polyester Marine Ropes?

Nylon and polyester both serve marine needs but differ dramatically in stretch behavior, environmental resistance, and load handling. Understanding how these polymers behave under load, sunlight and saltwater sets the stage for choosing the right line for your boat.

Key Differences: Nylon vs. Polyester Marine Ropes

| Feature | Nylon | Polyester |

|---|---|---|

| Strength & Stretch | High tensile strength, up to 30% stretch (absorbs shock). Loses up to 10% strength when wet. | Similar tensile strength, 5–10% elongation (predictable handling). Retains full strength when wet. |

| UV Resistance | More prone to UV degradation, losing 10–15% strength over time if not shielded. | Excellent UV stability, retaining over 90% strength after prolonged sun exposure. |

| Abrasion Resistance | Good, but flexes more under friction, potentially accelerating wear in high-chafe zones. | Slightly tougher against chafing due to higher rigidity and lower stretch. |

| Wet Strength | Absorbs up to 7% water, can lose up to 10% dry strength when wet, regains upon drying. | Barely absorbs moisture, retains nearly full strength underwater. |

How Do Nylon and Polyester Compare in Strength and Stretch?

Nylon offers high tensile strength and up to 30% stretch under load to absorb shock, whereas polyester delivers similar strength with just 5–10% elongation for more predictable handling. The stretchy nature of nylon protects against sudden jerks on an anchor rode, while polyester’s low stretch keeps sails and dock lines steady.

This contrast highlights how material stretch influences safety and control when docking or anchoring.

What Is the Impact of UV Resistance on Nylon vs Polyester Ropes?

Polyester exhibits excellent UV stability thanks to its aromatic polymer backbone, retaining over 90% of its strength after prolonged sun exposure. Nylon’s aliphatic structure is more prone to UV degradation, losing 10–15% strength over time if not shielded. UV resistance directly affects rope lifespan in constant sunlight.

How Does Abrasion Resistance Differ Between Nylon and Polyester?

Both fibres resist abrasion, but polyester’s higher rigidity and lower stretch make it slightly tougher against chafing over cleats and dock corners. Nylon flexes more under friction, which can accelerate wear in high-chafe zones. Choosing a rough-surface application often favors polyester for extended service.

Abrasion tolerance is critical for lines under frequent movement against rough edges.

Does Nylon Lose Strength When Wet Compared to Polyester?

Yes, nylon absorbs up to 7% water by weight and can lose up to 10% of its dry strength when wet, regaining it upon drying. Polyester barely absorbs moisture and retains nearly full strength underwater. Wet strength retention makes polyester the go-to for consistently damp environments like permanent dock lines.

Water absorption dynamics shape how ropes perform in rainy or submerged conditions.

Which Marine Rope Material Is Best for Specific Applications Like Docking and Anchoring?

Selecting rope material depends on application. Docking demands minimal stretch for position control, while anchoring benefits from shock absorption to protect gear and passengers. Load type, boat size and expected environmental stress guide the decision process.

Rope Material for Specific Marine Applications

| Application | Best Rope Type | Reason |

|---|---|---|

| Anchoring & Shock Absorption | Nylon | High elasticity and shock-absorbing mechanism dissipate sudden loads from waves and wind gusts, protecting gear and boat hardware. |

| Sailing Rigging (Halyards, Sheets) | Polyester | Low stretch provides stable lines for precise sail trim; UV resistance ensures longevity under sun exposure. |

| Permanent Dock Lines | Polyester | Low stretch maintains secure docking positions without bounce; excellent UV and wet strength retention for continuous exposure. |

| Heavy Boats / Dynamic Loads | Nylon (with appropriate diameter) | Added stretch can cushion big loads, preventing sudden jerks and protecting hardware. |

| Lighter Vessels / Position Maintenance | Polyester (with appropriate diameter) | Maintains position and minimizes movement due to low stretch. |

Why Is Nylon Preferred for Anchoring and Shock Absorption?

When Is Polyester Ideal for Sailing Rigging and Permanent Dock Lines?

Polyester’s low stretch and UV-resistant chemistry provide stable halyards, sheets and dock lines that won’t sag under continuous tension or degrade in sun. Predictable elongation enhances sail trim precision and secures docking positions without the bounce of more elastic ropes.

Such stability streamlines sailing performance and docking accuracy.

How Do Load Type and Boat Size Influence Rope Choice?

What Are the Advantages and Disadvantages of Nylon and Polyester Marine Ropes?

| Performance Factor | Nylon Advantage | Polyester Advantage | Nylon Limitation | Polyester Limitation |

|---|---|---|---|---|

| Elasticity | Absorbs shock from waves | Minimal stretch for steady hold | Can cause drift under constant load | Less shock buffering |

| UV Resistance | Suitable for intermittent exposure | Excellent long-term UV stability | Moderate UV degradation over time | Slight stiffness in cold weather |

| Wet Strength | Regains strength upon drying | Retains strength when wet | Up to 10% strength loss when wet | Limited stretch flexibility |

| Abrasion Tolerance | Flexible over chafe points | Higher chafe resistance | Faster wear under friction | Less elasticity under shock loads |

How to Choose the Best Marine Rope Based on Environmental and Usage Factors?

Selecting the optimal rope requires weighing UV exposure, abrasion points, weather extremes and rope construction types. Cost and maintenance further influence long-term value.

Environmental and Usage Factors for Rope Choice

| Factor | Nylon Consideration | Polyester Consideration | General Advice |

|---|---|---|---|

| Extreme Weather & UV Exposure | Suits cooler, shaded waters where shock absorption is priority; moderate UV degradation. | Outperforms in extreme heat and direct sunlight; maintains integrity and resists UV breakdown. | For tropical climates or long ocean passages, polyester ensures consistent performance. |

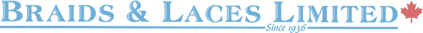

| Rope Construction | Often used in twisted construction for economy, or braided for shock absorption. | Common in braided (especially double-braid) for strength, low stretch, and abrasion resistance. | Braided offers smoother surfaces, higher strength-to-diameter, minimal stretch creep. Twisted is economical but can untwist. |

| Cost & Maintenance | Slightly less upfront cost, but may require more frequent inspections/replacement in UV-intense settings. | Commands a premium price, but durability reduces maintenance frequency. | Regular cleaning, UV covers, and chafe guards extend rope life regardless of material. |

Which Rope Material Performs Better in Extreme Weather and UV Exposure?

Polyester outperforms nylon in extreme heat and direct sunlight by maintaining structural integrity and resisting UV-induced breakdown. For tropical climates or long ocean passages, polyester ensures consistent performance. Nylon suits cooler, shaded waters where shock absorption is a priority.

Climate conditions help narrow material selection for durability.

How Does Rope Construction Affect Performance: Braided vs Twisted?

Braided ropes offer smoother surfaces, higher strength-to-diameter ratios and minimal stretch creep, while twisted ropes are simpler and more economical but can untwist under load and have uneven stress distribution. Double-braid construction combines a braided core for strength with a braided jacket for abrasion resistance, balancing performance and durability.

What Role Does Cost and Maintenance Play in Choosing Nylon or Polyester?

Nylon often costs slightly less upfront but may require more frequent inspections and replacement in UV-intense settings. Polyester’s durability reduces maintenance frequency but commands a premium price. Regular cleaning, UV covers and chafe guards extend rope life regardless of material, optimizing return on investment.

For custom lengths or specialized constructions, explore Custom Ropes | Braids and Laces Limited to tailor fibre type, colour and length to your vessel’s unique needs.

What Are the Alternatives and When to Consider Polypropylene or Other Marine Ropes?

Beyond nylon and polyester, polypropylene and advanced synthetic blends fill niche roles in buoyancy and cost-sensitive applications.

Comparison of Marine Rope Materials: Nylon, Polyester, and Polypropylene

| Property | Nylon | Polyester | Polypropylene |

|---|---|---|---|

| Buoyancy | Sinks | Sinks | Floats on water |

| Tensile Strength | High | High (similar to nylon) | Moderate (about half of polyester) |

| Stretch/Elongation | High (up to 30%) | Low (5-10%) | Moderate |

| UV Resistance | Moderate (degrades over time) | Excellent | Poor (degrades fastest in sunlight) |

| Water Absorption | Absorbs water (loses strength when wet) | Minimal absorption (retains strength) | Resists water absorption |

| Cost | Moderate | Higher | Low (most economical) |

| Typical Use | Anchoring, mooring, shock absorption | Dock lines, sailing rigging, permanent mooring | Rescue lines, buoy markers, temporary mooring |

When Is Polypropylene Rope Suitable for Marine Applications?

Polypropylene floats on water, making it ideal for rescue throw lines, buoy markers and temporary mooring where visibility and flotation matter more than strength. Its low cost suits short-term or budget projects but UV degradation limits long-term use.

Buoyancy features guide polypropylene’s specialized marine role.

How Do Polypropylene Properties Compare to Nylon and Polyester?

Polypropylene weighs 25–50% less than nylon or polyester and resists water absorption but only retains half the tensile strength of polyester and degrades faster in sunlight. Its lightweight nature and cost-effectiveness come with trade-offs in durability and load capacity.

Choosing the right line keeps boats secure and decks calm. If you need expert rope advice or custom display solutions for your next boat show.