Marine Rope Specifications: Essential Insights for Users

August 12, 2025

Table Of Contents:

- Marine Rope Specifications and Their Essential Uses

- Decoding Key Marine Rope Specifications

- Common Materials Used in Marine Rope Manufacturing

- Exploring Different Marine Rope Constructions

- Essential Uses Matched With Rope Specifications

- Guidelines for Choosing Appropriate Marine Ropes

- Maintaining Marine Ropes for Longevity and Safety

- Ready to Secure Your Next Voyage?

Choosing the right marine rope can be confusing, especially with so many specifications to consider. This blog post will break down key marine rope specifications, including common materials and construction types, to help you find the perfect rope for your needs. Readers will learn how to match different marine rope uses with specific qualities, ensuring safety and efficiency in their projects. Whether you’re a seasoned sailor or a casual boater, understanding these details can solve the problem of selecting the right rope every time. Let’s dive in!

Decoding Key Marine Rope Specifications

Understanding marine rope specifications is crucial for ensuring safety and performance in various applications. Key aspects include tensile strength and safe working loads, while diameter and length significantly impact usability. Assessing stretch characteristics, evaluating abrasion resistance, and considering factors affecting ultraviolet and weather resistance are essential for optimal choices. This overview sets the stage for a deeper look into each specific characteristic and its practical implications.

Understanding Tensile Strength and Safe Working Loads

When selecting marine rope, understanding tensile strength and safe working loads is essential to ensure reliability in critical applications such as towing. The tensile strength, which is the maximum load the rope can withstand before deformation, must be assessed alongside the rope‘s length and diameter to determine its suitability. In environments prone to corrosion, like coastal areas, choosing a kernmantle rope can enhance durability and performance, ensuring that both safety and effectiveness are prioritized in any marine undertaking.

The Significance of Rope Diameter and Length

The diameter and length of marine rope play a significant role in its overall performance and specific strength. A thicker rope might offer better strength, but it can also be heavier, which may not be ideal for certain applications like hoisting or towing. Additionally, the composition and construction of the rope can affect its flexibility and resistance to wear, particularly when paired with metal components or valves in marine settings, making it essential to choose dimensions that align with the intended use.

Assessing Stretch Characteristics for Different Applications

Understanding stretch characteristics is critical when selecting marine rope for various applications such as hoisting equipment or aquaculture. Ropes made from materials like Kevlar provide minimal stretch, making them ideal for scenarios requiring precise load control, whereas ropes with higher stretch can absorb shock loads, which is useful in dynamic environments. Additionally, when using ropes around water, it’s important to consider resistance to mildew to prevent degradation, especially in combinations with wire components that may further impact durability and performance.

Evaluating Abrasion Resistance for Durability

Evaluating abrasion resistance is key for ensuring long-lasting performance in marine ropes, especially for applications like mooring and dock work where contact with rough surfaces is frequent. Ropes with high abrasion resistance can endure wear and tear and resist fatigue, which is crucial when fastening knots or securing boats at the dock. Choosing a rope with the right specifications ensures that operators get the reliability they need, minimizing the chances of wear-related failures that can lead to costly accidents or repairs.

Factors Affecting UV and Weather Resistance

UV and weather resistance are key factors influencing the longevity and performance of marine ropes. Ropes made from high-quality fibers, like polyester, are particularly effective against wear and tear caused by sun exposure and harsh weather conditions. Users will find that selecting the right type of rope helps ensure their sails and other gear remain functional and reliable for longer periods, minimizing the need for replacements and providing peace of mind during their marine activities.

Understanding rope specs is just the beginning. Next, let’s look at the materials that make these ropes strong and reliable in the harshest conditions.

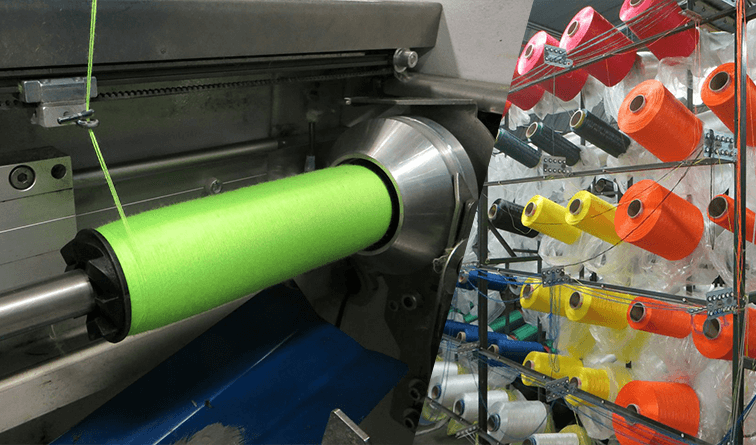

Common Materials Used in Marine Rope Manufacturing

Nylon ropes are known for their impressive performance in wet conditions, providing excellent friction and durability. On the other hand, polyester lines are favored for marine use due to their resistance to UV damage and abrasion. Polypropylene ropes offer unique buoyancy features, making them ideal for specific applications like bungee cords. High-modulus fibres like HMPE provide top-notch strength and efficiency. This section will compare these synthetic fibre performance metrics, highlighting their practical uses on yachts and with shackles.

Properties of Nylon Ropes in Wet Conditions

Nylon ropes stand out in wet conditions due to their impressive elasticity and robust textile properties. This unique combination allows them to endure significant stress and strain without losing their shape, making them ideal for rigging tasks where both strength and flexibility matter. Arborists often rely on nylon ropes for climbing and securing equipment, as their lightweight nature facilitates easy handling while maintaining the necessary durability for demanding applications.

Advantages of Polyester Lines for Marine Use

Polyester lines are exceptionally popular in marine applications due to their remarkable resistance to UV damage and abrasion, making them ideal for use on sailboats and with winch systems. Unlike some other materials, polyester ropes exhibit minimal creep, which means they maintain their shape and strength under load, ensuring reliability during climbing or securing tasks. The braided construction of polyester lines adds to their durability, enabling them to withstand harsh conditions while providing the performance needed for demanding activities in marine environments.

Characteristics of Polypropylene Ropes Including Buoyancy

Polypropylene ropes are a popular choice in marine applications, thanks to their unique buoyancy and low density, making them ideal for commercial fishing and other activities on the water. Unlike nylon, which tends to sink, polypropylene floats, allowing it to be easily managed during operations involving boats and ships. This buoyancy combined with its strength makes polypropylene yarn a valuable asset, particularly when used in nets or lines that must remain accessible on the surface.

Performance Aspects of High-Modulus Fibres Like HMPE

High-modulus polyethylene (HMPE) represents a cutting-edge option in marine rope manufacturing, known for its exceptional strength and low weight. It features a high melting point, giving it impressive resistance to heat and wear, making it suitable for demanding marine environments. With a low linear density, HMPE ropes provide high performance without the bulk, ensuring ease of handling and effectiveness during various applications, such as towing or securing equipment on boats.

Comparing Synthetic Fibre Performance Metrics

When comparing synthetic fiber performance metrics to natural fiber options in marine ropes, one must consider absorption and moisture resistance. Synthetic fibers, like nylon and polyester, usually outperform natural fibers by resisting water absorption, leading to less weight gain and better durability when wet. For example, while natural fibers can deteriorate over time due to moisture, plastic-based ropes retain their strength and form, making them the preferred choice for various marine applications.

With the right materials in hand, the focus now shifts to how these ropes are put together. Each construction method tells its own story, one that is essential for every sailor and fisherman.

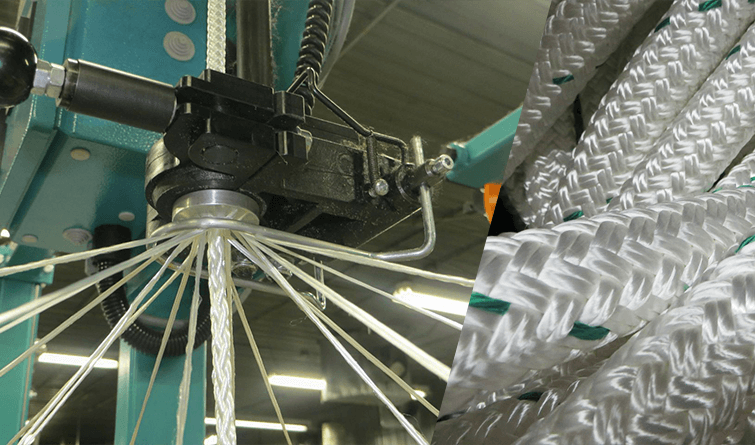

Exploring Different Marine Rope Constructions

Understanding the different constructions of marine rope is vital for optimal performance in various applications. This section will identify twisted rope builds and their characteristics, explore braided designs such as single, double, and solid options, and discuss core-sheath structures and their benefits. Furthermore, it will highlight how rope construction affects handling and knot holding, allowing for informed selections based on specific marine operations.

Identifying Twisted Rope Builds and Their Traits

Twisted rope builds offer a unique combination of strength and flexibility, making them popular for various marine applications. Their construction involves twisting multiple strands together, which creates a strong yet pliable rope that can handle significant loads. This type of rope is often favoured in situations where durability and ease of handling are essential, such as mooring and towing, providing users with reliable performance in challenging marine environments.

Understanding Braided Rope Designs Single Double and Solid

When it comes to braided rope designs, users often need to know the differences between single, double, and solid braids to make informed choices for their marine tasks. Single braid ropes offer flexibility and lightweight handling, making them great for applications such as fishing, while double braid ropes provide enhanced strength and abrasion resistance, perfect for towing and securing boats. Solid braid ropes, on the other hand, combine durability with a smooth surface, creating an excellent option for anchoring tasks where reliability is crucial. Understanding these distinctions can greatly aid in selecting the right rope for various marine needs.

Core-Sheath Rope Structures and Benefits

Core-sheath rope structures combine two distinct components—an inner core and an outer sheath—providing unique benefits for marine applications. This design allows the rope to maintain flexibility while enhancing abrasion resistance, making it ideal for tasks such as towing and securing loads. For instance, in high-wear situations like mooring, the durable outer layer protects the inner core, ensuring reliable performance over time and reducing the frequency of replacements.

How Construction Affects Handling and Knot Holding

The construction of marine rope significantly influences its handling and knot holding capabilities. For example, twisted ropes may offer flexibility, making them easier to handle but can make knots less secure. In contrast, braided ropes, particularly double braids, provide enhanced grip that secures knots better, making them a reliable choice for tasks that demand strong connections, such as towing and anchoring. Understanding these differences helps users select the appropriate type of rope to meet their specific marine needs while ensuring safety and efficiency in operations.

Selecting Construction Based on Intended Marine Operation

Selecting the right construction for marine rope is key to ensuring effective performance based on specific operations. For instance, when mooring a boat, users may prefer a double-braid rope for its excellent abrasion resistance and secure knot holding, which are crucial in demanding conditions. Understanding these nuances allows individuals to match rope construction to their marine activities, enhancing safety and efficiency while minimizing the risk of failures during critical tasks.

Each type of rope offers unique strengths. Knowing these can guide choices for every task ahead.

Essential Uses Matched With Rope Specifications

Reliable dock lines require specific specifications to withstand regular wear, while selecting anchor lines focuses on ensuring security and shock absorption. Mooring lines must be tailored for different conditions, and running rigging needs, such as halyards and sheets on sailboats, are crucial for performance. Each of these areas highlights the importance of matching rope specifications with practical uses, enhancing safety and efficiency on the water.

Requirements for Reliable Dock Lines

Reliable dock lines must have specific characteristics, ensuring they endure regular wear and the harsh marine environment. Users should prioritize ropes with excellent abrasion resistance, like double-braid polyester, which offer both durability and flexibility for secure mooring. Moreover, the right specifications, such as appropriate tensile strength and length, contribute to safe docking, minimizing the risk of accidents and ensuring peace of mind while at the dock.

Selecting Anchor Lines for Security and Shock Absorption

When selecting anchor lines, it’s crucial to choose ropes that offer both security and shock absorption. A good choice is a rope designed to handle dynamic loads without compromising strength, like double-braid nylon or nylon. These materials provide the needed elasticity to help absorb sudden forces while anchoring, which protects the boat and its crew during rough conditions. Ensuring the right specifications, such as tensile strength and diameter, can make all the difference in maintaining stability and safety while at sea.

Mooring Line Considerations for Various Conditions

When considering mooring lines for various conditions, it’s vital to understand the environment and its potential challenges. For instance, in rough waters, choosing a rope with high shock absorption—like double-braid nylon—can greatly enhance safety by preventing sudden jerks that might damage the vessel. Additionally, weather-resistant materials are essential in harsh climates to ensure the rope maintains its integrity over time, giving boaters peace of mind while secured at the dock.

Running Rigging Needs Halyards and Sheets on Sailboats

Running rigging on sailboats, which includes halyards and sheets, plays a vital role in sail control and overall performance. Choosing the right marine rope for these applications is essential, as halyards must be lightweight yet strong enough to support the weight of the sail while being easy to handle. Sheets, on the other hand, benefit from ropes that combine durability with excellent grip to secure sails under tension, ensuring they respond quickly to adjustments while on the move. Understanding these specifications helps sailors optimize their sailing experience, enhancing both safety and efficiency on the water.

Specifications for Towing Lines and Safety Gear

When it comes to selecting towing lines and safety gear, choosing the right marine rope specifications is paramount. Ropes should ideally exhibit high tensile strength and excellent shock absorption to handle dynamic loads during towing operations. For instance, a double-braid nylon rope offers the necessary resilience and elasticity, enhancing safety in challenging conditions by effectively absorbing impacts that could otherwise jeopardize the vessel and crew.

Choosing the right rope is more than just a matter of specifications; it’s about knowing the task at hand. The next steps will guide you through selecting the perfect marine ropes for your needs.

Guidelines for Choosing Appropriate Marine Ropes

Choosing the right marine rope is about matching the type to the vessel and environment. It’s essential to determine the appropriate strength and diameter while balancing performance with budget. Understanding manufacturer data sheets is key, along with considering handling feel and spliceability. These aspects help ensure effective and reliable rope choices for various marine applications.

Matching Rope Type to Your Vessel and Environment

Choosing the right rope type to match your vessel and environment can significantly enhance marine safety and performance. For instance, a sailboat operating in rough waters may benefit from high-stretch nylon rope for its shock absorption capabilities, while a fishing boat may prefer buoyant polypropylene for ease of handling. By assessing factors such as the size of the vessel and the specific challenges of the marine environment, users can select ropes that provide durability and reliability, ensuring smooth operations while out on the water.

Determining the Right Strength and Diameter Needed

Determining the right strength and diameter for marine ropes is essential for ensuring safety and performance in various applications. For instance, a small sailing boat may require thinner lines for halyards and sheets, while a larger vessel towing heavy loads needs thicker, stronger ropes to handle the strain. By carefully evaluating the intended use, the environment, and potential loads, users can confidently select ropes that provide the durability and reliability needed for efficient marine operations.

Balancing Performance Features With Cost Considerations

When selecting marine ropes, it’s essential to strike a balance between performance features and cost. Investing in high-quality ropes with excellent abrasion resistance and tensile strength can save money in the long run by reducing replacements and maintenance. For instance, while a slightly more expensive nylon rope may seem like a stretch on the budget, its durability and shock absorption capabilities will offer peace of mind during rough conditions, ultimately proving to be a cost-effective choice for marine operations.

Interpreting Manufacturer Data Sheets Correctly

Understanding how to interpret manufacturer data sheets is vital for selecting the right marine ropes. Users should focus on key specifications such as tensile strength, diameter, and material type to ensure the chosen rope meets their specific needs. By carefully examining these details, individuals can make informed decisions that enhance safety and performance for each unique marine application.

Factoring in Handling Feel and Spliceability

When selecting marine ropes, it’s vital to consider handling feel and spliceability to ensure ease of use in various applications. Ropes that are too stiff may hinder effective handling during operations, while those that allow for smooth handling can enhance safety and efficiency. Moreover, a rope that is easy to splice facilitates creating secure connections, making it essential to choose ropes that provide both comfort during use and straightforward splicing capabilities, ultimately supporting reliable performance in marine environments.

Choosing the right marine rope is just the beginning. To ensure safety and longevity, knowing how to care for those ropes is equally vital.

Maintaining Marine Ropes for Longevity and Safety

Effective maintenance of marine ropes is essential for ensuring longevity and safety during their use. Key practices include cleaning methods for saltwater exposure, regular inspections for wear and chafe, and proper storage techniques away from sunlight and chemicals. Additionally, recognizing signs indicating the need for replacement and applying basic finishing techniques to the ends can significantly enhance rope performance and reliability in diverse marine environments.

Effective Cleaning Methods for Saltwater Exposure

To keep marine ropes in top condition after exposure to saltwater, rinsing them with fresh water is a must. This simple step helps remove salt and debris that can lead to wear and tear over time. After rinsing, it’s beneficial to hang the ropes in a shaded area to dry completely, preventing mildew and ensuring that they remain strong and reliable for various applications when out on the water.

Regular Inspection Practices for Wear Chafe and Damage

Regularly inspecting marine ropes for wear, chafe, and damage is crucial to maintain their performance and longevity. Users should look for signs such as fraying, discoloration, or any stiffness that may indicate the rope is nearing the end of its life. By establishing a routine check—especially after heavy use or exposure to harsh conditions—boat owners can ensure their ropes remain reliable for various marine activities, ultimately enhancing safety on the water.

Proper Storage Techniques Away From Sunlight and Chemicals

Proper storage of marine ropes is essential for maintaining their longevity and performance. Keeping ropes away from direct sunlight and harsh chemicals protects them from UV degradation and potential damage that could shorten their lifespan. Ideally, storing ropes in a cool, dry, and shaded area, such as a dedicated storage bin or cover, ensures they remain in top condition for various marine applications, preventing issues that might arise from environmental exposure.

Recognizing Signs That Indicate Rope Replacement Is Needed

Recognizing when to replace marine ropes is crucial for safety and performance during use. Signs such as fraying, significant discoloration, or stiffness indicate that the rope may be compromised and could fail under stress. Being proactive about rope replacement enhances the reliability of marine operations, ensuring that the equipment used onboard remains effective and secure.

Basic Rope Finishing Techniques for Ends

Basic rope finishing techniques for the ends of marine ropes are essential for preventing fraying and ensuring longevity. Techniques such as melting the ends of synthetic ropes or using tape can help secure the fibers and maintain their integrity during use. Properly finished rope ends not only enhance performance but also contribute to safety in various applications, making it crucial for users to implement these simple yet effective methods in their maintenance routine.

Ready to Secure Your Next Voyage?

Don’t leave your safety and efficiency to chance. Equip your vessel with the highest quality marine ropes tailored to your specific needs. Explore our comprehensive selection and find the perfect solution for every task, from critical docking to demanding offshore operations. Ensure reliability, durability, and peace of mind on every journey.